Modern Molding Photo Shoot

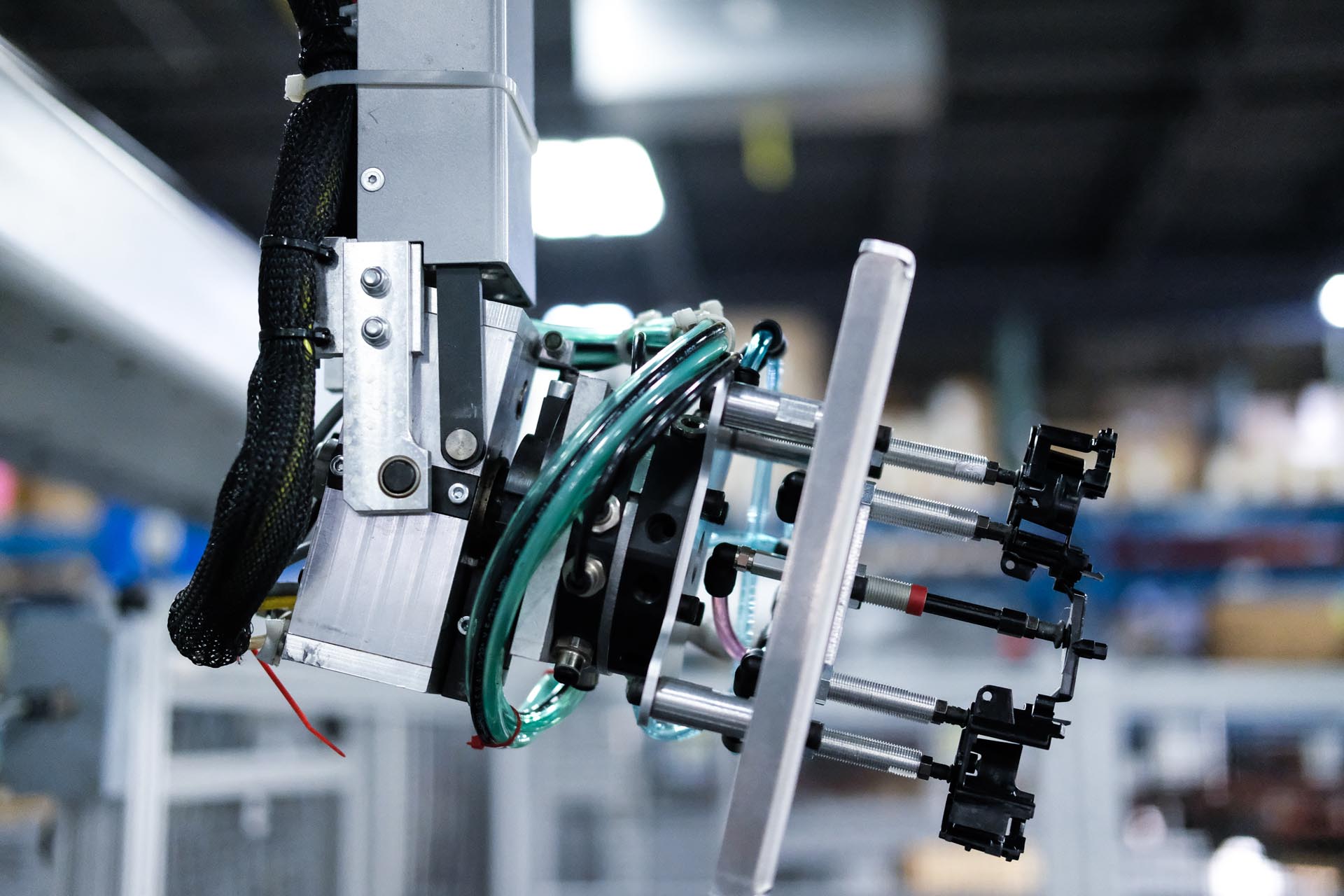

We recently had a photo shoot here at Modern Molding.

Since 1981

Since 1981, MMI’s highly skilled and responsive technicians have brought state-of-the-art knowledge and support to every injection molded plastic part we produce. Customers have come to rely on MMI’s expertise and capabilities that other injection molding companies cannot provide. Modern Molding not only produces the parts, but also manufactures their own molds in-house. MMI is a complete state of the art “one-stop shop,” a factor that saves customers both time and money.

Electronics, telecommunications, construction/agricultural equipment, off-road vehicle, window/door manufacturing, commercial cleaning, gas detection, as well as many other OEMs. With custom-molded and tooled parts that use engineered-grade resins, Modern Molding is far more than a “shoot and ship” injection molding company.

Modern Molding, Inc.

We recently had a photo shoot here at Modern Molding.

Modern Molding, Inc. is proud to announce that we were

Modern Molding has been honored “Small Manufacturer of the Year”